Simulation of Processes in Shaft Kilns

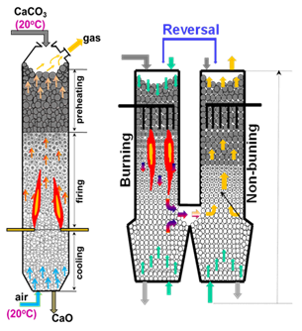

Lime Burning in Parallel Flow Regenerative Shaft Kilns (PFR) and Counter Flow Single Shaft Kilns (CFS)

The program calculates the axial profiles of:

- Gastemperature

- Core temperature of five stone fractions

- Surface temperature of five stone fractions

- Mean stone temperature

- Limestone decomposition (residual CO2)

- mean value

- individual value of every size fraction

Simulated results are:

- Energy consumption

- Residual CO2 content

- Flue gas temperature

- Flue gas composition (dry and wet)

- Discharge stone temperature

- Pressure drop

- Wall heat losses.

All results are presented using figures and Excel tables.

The program can be installed on every laptop.

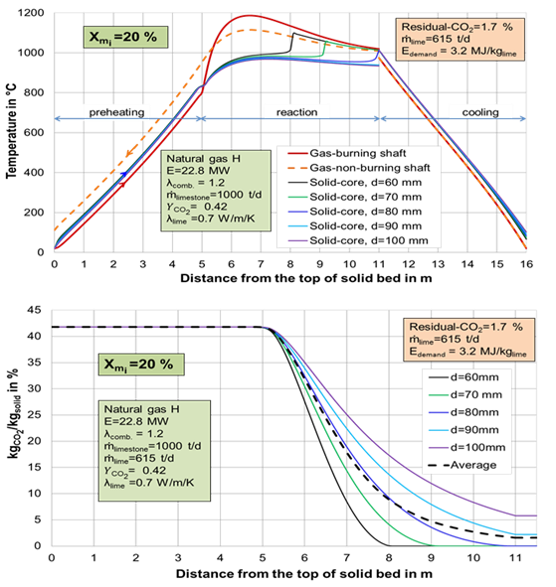

Profile of core temperature and residual CO2 in PFR Kiln

Economical advantages of the program:

- Optimization of the calcination process for energy consumption, quality and regulation by changing

- Throughput

- Size distribution of stones

- kind of fuel

- kind of limestone

- kiln geometry - Training of technical staff

Analogous to an aircraft simulator the kiln can be operated by persons using various conditions. Therewith, the understanding of the process and the influence of the lot of parameters can be trained - Reduction of maintenance costs e. g. refractory replacement

- Interpretation of measured kiln data

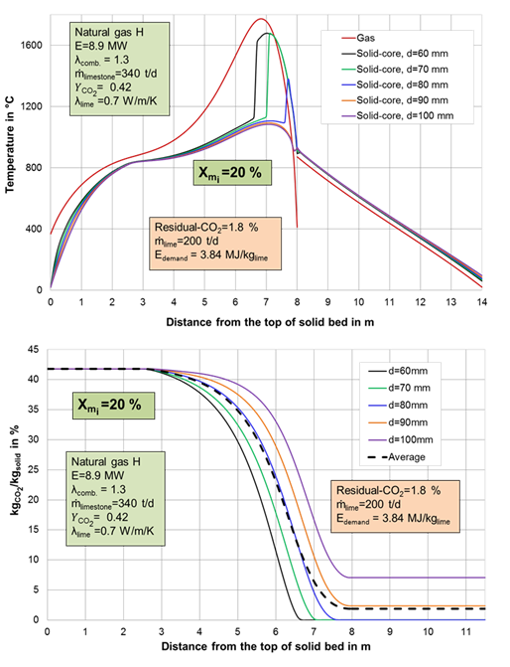

Profile of core temperature and residual CO2 in CFS Kiln

Inserted and investigated parameter

1. Interface: Kiln Geometry and Environment

- Length of preheating zone

- Length of burning zone

- Length of cooling zone

- Internal diameter or cross sectional area

- Working refractory (thickness and conductivity)

- Insulation refractory (thickness and conductivity)

- Environment conditions (temperature, wind speed)

- Insert temperature of cooling air

- Charging temperature of limestone

2. Interface: Process parameter and lime properties

- Mass flow input of limestone for every shaft

- Void fraction

- Mean particle diameter or

- Particle size distribution up to five classes

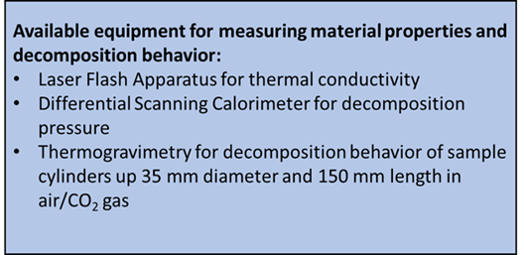

- Material properties of limestone and lime

- Composition (CaCO3, MgCO3, inerts, water)

- Density

- Decomposition (equilibrium) pressure

- Thermal conductivity

- Reaction coefficient

3. Interface: Parameters of Fuel

- Type of fuel (gaseous, liquid, solid)

- Gaseous fuels:

- Composition, heating value will be calculated

- Heating value, if composition is not known - Liquid fuels: heating values (typical values are given)

- Solid fuels: heating values (typical values are given)

4. Interface: Combustion Parameters

- Power of burners

- Mass or volume flow of fuel

- Combustion air at top (PFR kilns)

- Combustion air through lances (PFR- and CFS-kilns)

- Cooling air burning shaft (PFR kiln)

- Cooling air regenerative heating shaft (PFR kiln)

- Cooling air (CFS-kiln)

Competence:

The program is based on

- Ten Ph.D. studies at the Institute of Fluid Dynamics and Thermodynamics at Otto von Guericke University Magdeburg

- Several research projects in cooperation with the German Lime Association funded by the German Ministry for Economic Affairs.

- It is validated with a lot of measurements in PFR- and CFS-kilns.

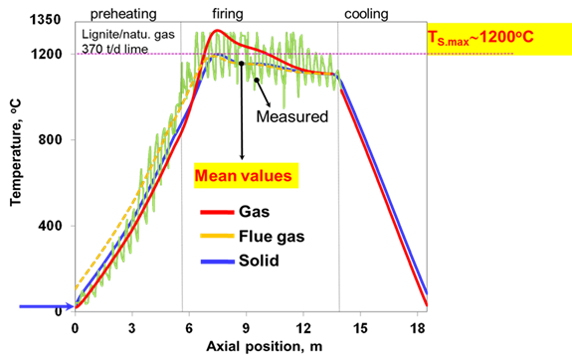

Validation of measured and calculated temperature profiles

Doctorates on the research focus

- Dr.-Ing. Bassem Hallak: Simulation und Analyse des Kalkbrennens in Normalen-, GGR- und Koksschachtöfen (06.12.2019)

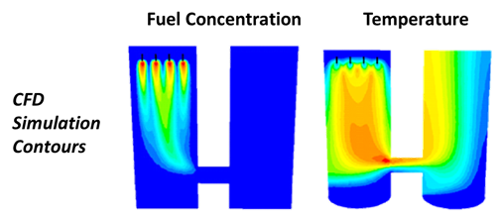

- Dr.-Ing. Kamyar Mohammadpour: CFD Simulation of Reactive Flow in Lime Shaft Kilns using Porous Media Model and Experimental Validation (28.11.2019)

- Dr.-Ing. Nyein Nyein Linn: Combustion Behaviour of Lumpy Coal Particle under Shaft Kiln Conditions (26.09.2017)

- Dr.-Ing. Ali Mohammed Ridha Al-Khalaf: Experimental and Numerical Analysis of Flow Mixing in Packed Beds (20.03.2017)

- Dr.-Ing. Purna Chandra Gourisankar Sandaka: Calcination behavior of lumpy limestones from different origins (06.04.2016)

- Dr.-Ing. Duc Hai Do: Simulation of Lime Calcinations in Normal Shaft and Parallel-Flow-Regenerative Kilns (25.04.2012)

- Dr.-Ing. Magda El-Fakharany: Process Simulation of Lime Calcination in Mixed Feed Shaft Kilns (09.01.2012)

- Dr.-Ing. Zhiguo Xu: Reduced Model for Flow Simulation in the Burner Region of Lime Shaft Kilns (19.10.2010)

- Dr.-Ing. Thomas Schwermann: Untersuchung des Optimierungspotentials des Ringschachtofens zum Brennen von karbonatischem Gestein (10.04.2007)

- Dr.-Ing. Agnieszka Bes: Dynamic Process Simulation of Limestone Calcination in Normal Shaft Kilns (10.04.2006)

Selected publications of the research area

- Mohammadpour, K.; Al-Khalaf, A.; Specht, E.: CFD Simulation of Cross Flow Mixing in a Packed Bed using Porous Media Model and Experimental Validation. Computational Particle Mechanics (2018). (30.08.2018 published online) DOI: 10.1007/s40571-018-0203-x

- Sandaka, G.; Specht, E.: Influence of material properties on limestone decomposition. Cement Lime Gypsum 3 (2018) 52-56.

- Mohammadpour, K.; Woche, H.; Specht, E.: CFD Simulation of Parallel Flow Mixing in a Packed Bed using Porous Media Model and Experiment Validation. Journal of Chemical Technology and Metallurgy, 52, 3, 2017, 475-484.

- Sandaka, G.; Al-Karawi, J.; Specht, E.; Silva, M.: Thermophysical properties of lime as a function of origin (Part 4): Conductivity: Cement Lime Gypsum 3 (2017), 36-41.

- Hallak, B.; Herz, F.; Specht, E.; Gröpler, R., Warnecke, G.: Simulation of limestone calcination in normal shaft kilns – Part 3: Influence of particle size distribution and type of limestone. Int. Journal of Cement Lime Gypsum 3 (2016), 64-68.

- Hallak, B.; Specht, E.; Herz, F.; Gröpler, R.; Warnecke, G.: Simulation of lime calcination in Normal Shaft Kilns – Influence of process parameters. Int. Journal of Cement Lime Gypsum 10 (2015) 46-50.

- Hallak, B.; Specht, E.; Herz, F.; Gröpler, R.; Warnecke, G.: Simulation of lime calcination in Normal Shaft Kilns – Mathematical Model. Int. Journal of Cement Lime Gypsum 9 (2015) 66-71.

- Hallak, B.; Herz, F.; Specht, E.; Kehse, G.: Energy consumption and CO2 content in the flue gas of normal shaft kilns: Part 2: Influence of the limestone quality and the process parameter. Cement, Lime, Gypsum 12 (2014) 38-41.

- Hallak, B.; Herz, F.; Specht, E.; Kehse, G.: Energy consumption and CO2 content in the flue gas of normal shaft kilns: Part 1 Influence of the excess air number. Cement, Lime, Gypsum, 11 (2014) 60-66.

- Hai Do, D.; Specht, E.:Measurement and Simulation of Lime Calcination in Normal Shaft Kiln. Journal of ASTM International 2012. Materials Performance and Characterization 1 No. 1 (2012) 1-14.

- Hai Do, D.; Specht, E.; Kehse, G.; Schmidt, O.; Frank, S.: Comparisons of simulated and measured temperature profiles in PFR and RCE kilns. Int. Journal of Cement Lime Gypsum, 7 (2012) 64-72.

- Hai Do, D.; Specht, E.; Kehse, G.; Ferri, V.; Christiansen, T. L.; Bresciani, P.: Simulation of lime calcination in PFR kiln – Influence of source and size of limestone. Int. Journal of Cement Lime Gypsum, 4 (2012) 56-65.

- Cheng, C.; Specht, E.; Kehse, G.: Influence of origin and material property of limestone upon its decomposition behaviour in shaft kilns. Cement, Lime, Gypsum 60 (2007) No. 1, 51-61.

- Cheng, C.; Specht, E.: Reaction rate coefficients in decomposition of lumpy limestone of different origin. Thermochimica Acta 449 (2006) 8-15.

- Specht, E.; Kainer, H.; Jeschar, R.: Reaction, Pore Diffusion and Thermal Conduction Coefficients of Various Magnesites and their Influence on the Decomposition Time. Radex-Rundschau (1986), 4, 248-268.

- Kainer, H.; Specht, E.; Jeschar, R.: Pore diffusion, reaction and thermal conduction coefficients of various limestones and their influence on decomposition time. Cement, Lime, Gypsum 39 (1986), 5, 259-268 (deutsch). Cement, Lime, Gypsum 39 (1986), 7, 214-219 (englisch).