Combustion Processes

The post combustion of CO2 and H2 exhaust gases is carried out in many cases with the radial air injection in cylindrical combustion chambers.

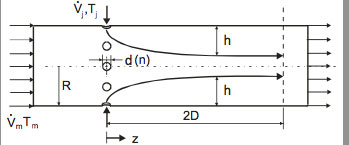

Figure 1 shows the principle of a combustor for a single-stage air injection. Of particular interest to the co-worker, the question is in which n number of nozzles and in which nozzle diameter d for a particular mixing path a substantial temperature uniformity is achieved over the cross section. Numerical calculations with the program system FLUENT showed that the temperature homogeneity of the dimensionless depth h / R of the air jet is dependent (R is the radius of the combustion chamber). The determining physical size for the depth of penetration, the ratio of the dynamic pressures J was (also referred to as pulse current ratio) determined.

Figure 1: Scheme combustion chamber with radial air injection

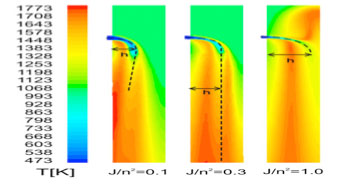

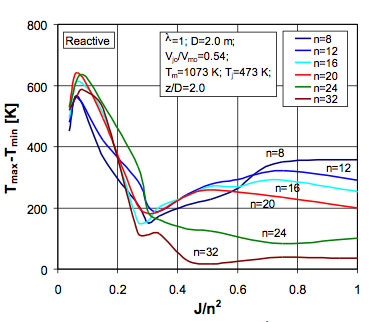

Figure 2 shows temperature profiles at different pulse current conditions J / n2. The left edge of images representing the channel wall and the right edge the channel center . The radial deflection of the jet stream is completed after 0.25 diameters and is marked in this area. Through increases in temperature leads, the edges will burn. An increase in the radial supplied gas stream increases the values J / n2 and there is a shift of the flow paths in the direction of center of the channel. The smallest temperature differences according to a length of 2 diameters arise in J / n2 = 0.3. Figure 3 shows the temperature differences are compared for a mixing distance of 2 diameters depending on J / n2. Parameter is the number of nozzles n.

Figure 2: temperature fields in a combustion chamber with single-stage air injection

For all investigated nozzle numbers forms in J / n2 = 0.3 a relative minimum. In nozzle numbers 20 to cause deviations from J / n2 = 0.3 upwards as well as downwards always an increase of the temperature differences in the combustion chamber cross-section . If the nozzles number 24 and higher, is caused by an exceeding = 0.3 J / n2 , a further reduction of the temperature differences. For a given number of nozzles n = 0.3 the optimum nozzle diameter d can be determined by the boundary condition J / n2.

Figure 3: Influence of the number of nozzles and of J / n2 to the temperature differences

Selected publications of the research area Verbrennungsprozesse / Combustion Processes

- Nirmolo, A.; Woche, H.; Specht, E.; Skroch, R.: Mixing of jets in cross flow after double rows of radial injections. Chemical Engineering and Technology 31 (2008) 2, 294-300.

- Nirmolo, A.; Woche, H.; Specht, E.: Temperature Homogenisation of reactive and non-reactive Flows after Radial Jets Injections in confined cross-flow. Engineering Applications of Computational Fluid Mechanics. 2 (2008)1, 85-94.

- Nirmolo, A.; Woche, H.; Specht, E.: Gas mixing in cylindrical chambers after radial jets injection Progress in Computational Fluid Dynamics 7 (2007) 447-456,

- Nirmolo, A.; Woche, H.; Specht, E.: Auslegungskriterien zur Temperaturvergleichmäßigung in Brennkammern mit radialer Lufteindüsung. Gaswärme int. 55 (2006) 338 - 341

- Woche, H.; Nirmolo, A.; Skroch, R.; Specht, E.: Intensivmischung von radialen Düsenstrahlen mit einer Hauptströmung. Gaswärme International 54 (2005) 301-307.

- Ulzama, S.; Specht, E.: Reaction Kinetics of Carbon-Carbon Dioxide Reaction in an Environment of CO2-CO-N2 at Elevated Temperatures. Industrial and Engineering Chemistry Research (submitted 05/06) Specht, E.; Sahoo, R.: Analytisches Modell zur Simulation der Verbrennung der Flüchtigen von festen Brennstoffen und deren Einfluss auf die Erwärmung. 23. Deutscher Flammentag, VDI Berichte 1988 (2007).

- Ulzama, S.; Specht, E.: An analytical study of droplet combustion under microgravity: quasi-steady transient approach. 31st International Symposium on Combustion. 06-11 August 2006 in Heidelberg (Germany). Proceedings of the Combustion Institute, 2301-2308.

- Ulzama, S.; Specht, E.: Modeling the reaction mechanism of lumped porous coke particles during industrial processes. Indian Chemical Engineering Congress 14 - 17 December 2005, New Dehli. Giese, A.; Specht, E.: Einfluss der Form auf die Verbrennung von Kohlepartikel mit gleichem Siebdurchmesser. 20. Deutscher Flammentag. VDI Berichte (2001) Nr. 1629, 109-114

- Giese, A.; Specht, E.: Influence of Shape on the Burn-off of Coke Particle. Proceedings of the 3rd European Congress of Chemical Engineering, Nürnberg 26-28 June (2001). Kurzfassung: Chemie Ingenieur Technik 73 (2001) 686.

- Jeschar, R.; Specht, E.; Bittner, H.-G.: Brennstoff- und Kosteneinsparung durch Sauerstoffanreicherung der Verbrennungsluft in Industrieöfen. Stahl und Eisen 108 (1988), 835-840.