Cooling Strategies to equalize Surface Hardness and minimize Distortion

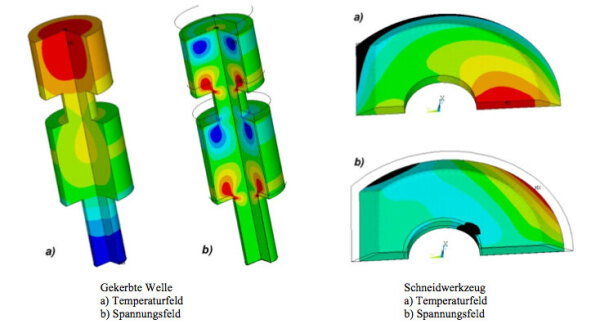

After hardening processes or after the cooling of heat treatment processes occur an uneven distribution of surface hardness and an undesirable deformation (distortion) on the workpieces. On cooling with liquids , the heat transfer due the Leidenfrost problem with the undefined collapse of vapor film, is different in spatially and time. Therefore, new cooling methods ( evaporative cooling , cooling nozzle array ) are developed to adjust the local history of the heat transfer in a targeted manner. The temperature , microstructure , voltage and strain field in the workpiece is calculated based on coupled FEM . Hence strategies are determined to adjust the heat transfer field to equalize the hardness and minimize distortion .

The calculations show good agreement with the corresponding experimental values, that have been identified at the Institute of Materials Science at the University of Bremen for components of complex geometry. For long sections of steel has been shown that they can be cooled without distortion through targeted heat dissipation .

Mathematical simulation of a deterrent in a nozzle array

Careful adjustment of the local heat transfer coefficient , the voltage spikes can degrade and minimize the delay . For this purpose, the cooling strategies are developed and the technological implementation in the experiment are investigated.